Unraveling the Secrets of Injection-Molded Filter Cartridge End Cover and Expanded Metal Mesh

Ever wonder how a filter cartridge operates? Filter cartridges are different types which remove dirt and other unwanted things from liquids, gases, or air. It is used everywhere whether in our home, schools or factories. These filters are important to ensure that everything we use daily is, in fact safe and clean. This blog post gives you some information on two key parts used in filter cartridges the End Covers and Expanded Metal Mesh.

Filter Cartridge End Cap Technology

The Filter Cartridge End Covers are the very crucial parts of filter cartridge. These are the parts that serve as a crucial in linking every thing and maintain seal of the filter so no harmful element can not pass via it. Injection molding is the process used to make these end covers. This involves melting plastic and placing it in a mold After the plastic cools, you have an end cover formed in solid state.

The design of the end cover is crucial. Other plastic products everything together, but it must be flexible enough that you can slide your shaft in and out at will. Being able to do necessary, as we will need sometimes (or often) either change the filter or clean it up. The end cover must also be capable of withstanding the pressure generated as a result of operation vibrating screen. It will break, and then the filter does not work properly.

How Does Expanded Metal Mesh Work2

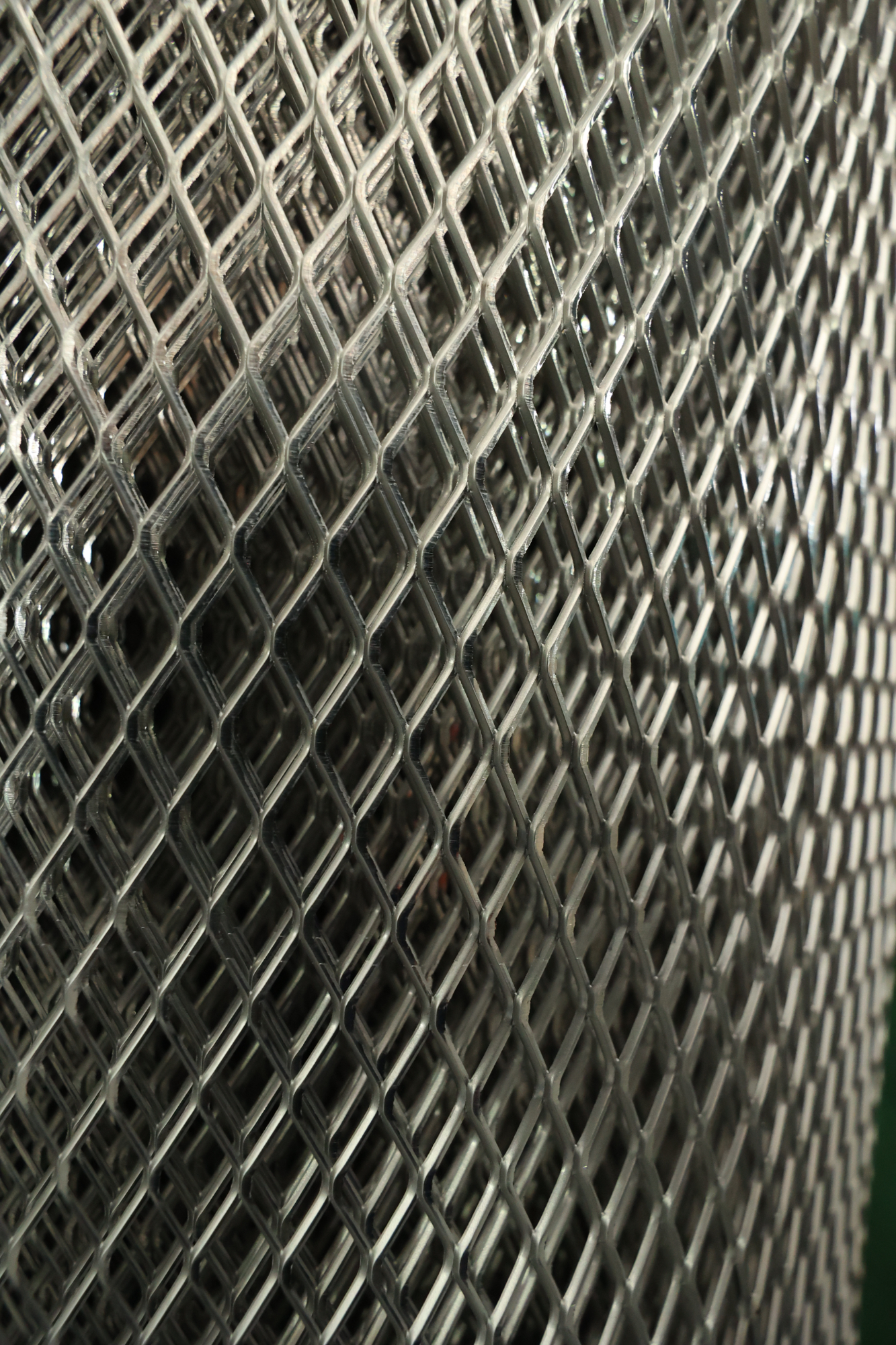

Also the expanded metal mesh a very important part of the filter cartridge. This mesh assists the filter to work more efficiently. Think of it like cutting and stretching a piece of metal this process yields a pattern with many little holes, much like that on the net.

The addition of the metal mesh in the Sheet metal stamping mold will expand its space for more liquids, gases or air to flow across. submitted by JDLedesma true allows the filter to capture more dirt and filth of that we want in water or air The mesh also ensures that the pressure is distributed equally over the entire filter. An even distribution of pressure is important to protect the filter while it goes to work.

What Importance do the Material And Quality of End Covers Hold?

What is Most Important: the Material, of Course ? The tensile strength (how much pull per inch before the end cover rips or tears) and flex are determined in easy to understand terms: how tough will this material be and for how long? The end covers can be made of different types of plastic. Others are more stiff and will simply snap instead of bending, some plastics flex a good amount.

There is also the way that plastic are manufactured. This Injection mold allows manufacturers to maintain a top strength and flexibility of the end cover, for example by managing temperature as well pressure during injection molding process. This allows them to make end covers which are suitable for the job they have in use.

Why Expanded Metal Mesh is Used in Harsh Conditions?

Obviously, since filter cartridge is operating under a high pressure they have to perform optimally where be it in factories or even at your own house. This requires them to be compatible with highpressure environments and provide excellent filtration of impurities from any kind of liquid, gas or air. Expanded Metal Mesh A Great material for these Tough Conditions It is designed to withstand the pressure and efficiently clean out liquids, gases or air.

The mesh is also essential for ensuring even distribution of the pressure over the entire surface area of filter. An even distribution of pressure is key to prevent the filter from failing e during highpressure conditions.

Improved Filter Cartridges Created With New Technology

The technology of making filter cartridges has improved significantly in recent years. Advanced techniques that can be used for end covers which execute complex and more detailed designs. It allows manufacturers to build more efficiently shaped end covers. Newer materials that are stronger more flexible, last longer than the older ones have also been introduced.

The advent of quicker, more efficient injectionmolding has certainly helped as well. Which gives us faster filter cartridge production time and with this, less waste. This technological evolution allows to produce filter cartridges that are more respectful of our environment and, as an added value through it all makes also liquids, gases and air cleaner.

Filter cartridges are extremely essential and help keep our liquids, gases or air clean safe. Both the end cover and expanded metal mesh are correctly designed for an ideal working performance of the filter. Apart from everything, the end cover need to be strong as well flexible since it is going to hold all inside and mesh for improved functioning of the filter(introducing more surface area). Knowing what those components are made out of help us understand why our filter cartridges can be bettermade. In a word, thanks to new technology such as nanotechnology and other innovations our filter cartridges are ready for many years ensuring we have clean water and good air in long term.

Comments

Post a Comment