Injection Molding Machine Safety Features: Protecting Operators

Safety is very important in all times while using injection molding machines. That means the machines need to have the appropriate safety features to keep the people using them safe. we do care about our machines and about everyone who operate on it. In this piece, we will be discussing what makes safety features so important, how they may help prevent accidents, and what specific ones you should be looking for when working with these machines.

Injection Molding Machines: Why Safety Features Are Important

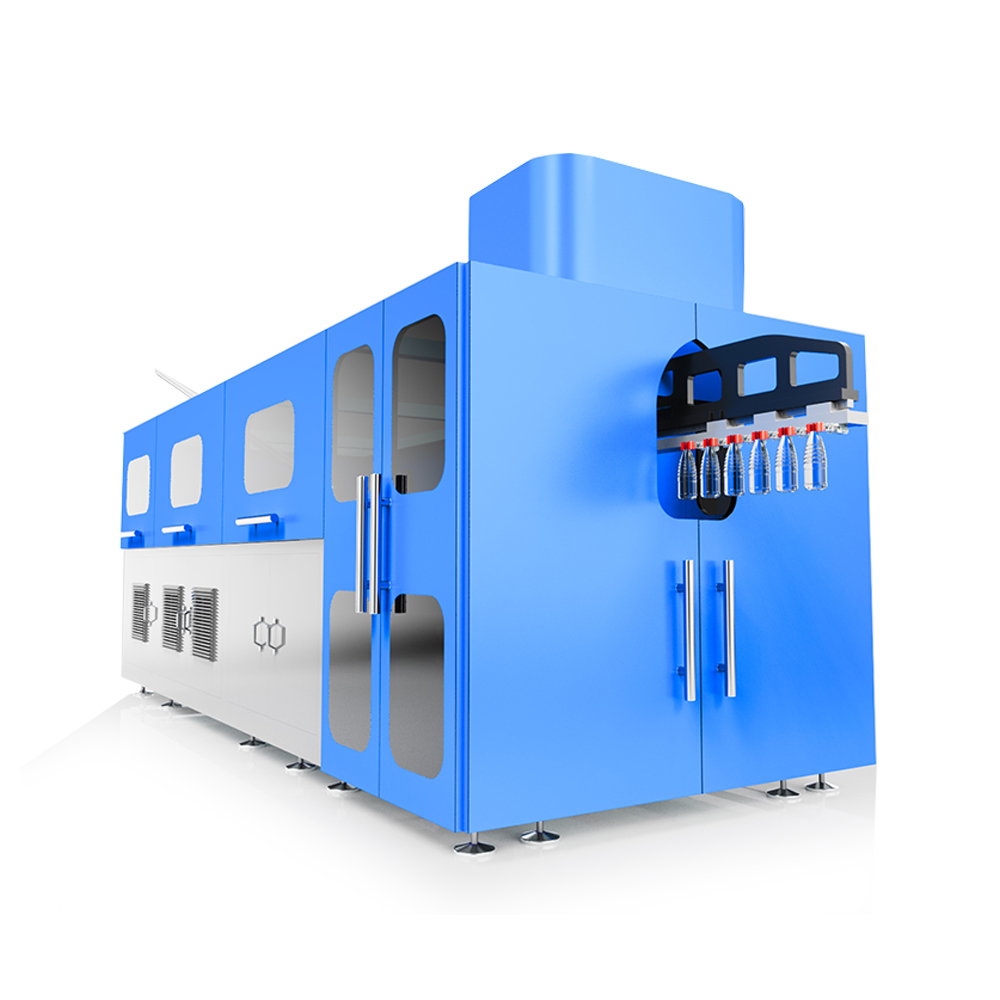

Safety features in injection molding machines are critical as they ensure the safety of the semi automatic pet blowing machine while using these machines. Advanced safety technology features are designed to prevent accidents and injuries before they occur. They make sure the machine is functioning properly and it is safe for humans to drive it. These safety features help prevent accidents from occurring in the first place, reducing the likelihood of serious injury to someone working near the machine, and preventing potential damage to the machine itself. So it is important to know these features to provide a safer work environment.

How Safety Features Prevent Accidents in Injection Molding

Injection molding safety features will prevent accidents These include things like overheating, pet preform blowing machine such as power surges, and mechanical failures within the machine itself. One important safety feature is the emergency stop button, for example. This is a button that lets operators quickly shut down the machine if something goes wrong, whether a part fails, or someone is at risk. This feature ultimately diminishes the risk for serious accidents, and is key if you want to keep everyone who is working with that machine to be safe.

Injection Molding Machines Safety: A Must-Know Guide

Injection Molding machines can be dangerous to operate so it is very vital to follow these safety guidelines to maintain a safe workplace.

Always use the proper safety equipment: This includes things like gloves, goggles, and ear protection. Wearing the proper equipment can shield your body from injury.

Regular maintenance: Get the machine checked regularly to keep it in good working condition. Regular care can help prevent some of the issues that can result in an accident.

Maintain a clean and organized work environment A clean and organized work environment can help reduce accidents. Just make sure that there is no hindrance on the Make sure that there are no obstacles in the way.

Listen up: Stay aware of safety instructions and guidelines from the manufacturer. These instructions are meant to protect you.

Don’t try to fix or modify the machine if you’re not trained and empowered to do so: Do not try to fix or change the machine. Of course, you should always consult with someone who is qualified to do this. On the whole, understanding how to use injection molding machines in a way that minimizes the vast majority of risk boils down to these key rules of thumb, as well as utilizing machinery with the requisite safety additions built in.

When Buying Injection Molding Machines

Injection molding machine operators should look for several essential safety features that will promote optimal safety:

STOP emergency button: This is a very important feature so that an operator can quickly stop the working of the machine in case of any emergency. It can save lives and avoid injuries.

Shields: These are safety devices that protect workers from the moving parts of a machine. They stop bodily appendages from approaching hazardous zones.

Overheat protection: This feature is very important because it prevents the machine from overheating, which can harm the machine or even cause a fire. That keeps the machine grinding away safely.

Automatic shut off a feature designed to shut the machine down if it senses anything unusual with its operation. Such measures can be made to stop accidents before happening.

Safety interlocks: These mechanisms prevent the machine from powering on unless certain safety requirements are fulfilled. This guarantees that all is safe before the machine goes into use. With these safety features in place, operators can safeguard themselves and prevent accidents with injection molding machines.

Injection Molding Machine Features that Enhance Workplace Safety

Injection molding machine safety features can substantially improve workplace safety when they put the proper preventative measures in place. This also protects the employees from having any accidents or injuries. Safety features An area of machine safety improvements is the addition of safety features that, when operating a machine, can help create a new safe working environment for operators. We at pet stretch blow forming machine to make injection molding machines with top-notch safety features to promote customers' safety and well-being.

In summary, safety mechanisms play an essential role in operations of injection molding machines. They assist in danger avoidance, operator protection, and workplace safety. Operators can be sure that they work in a very safe and sound environment by complying to safety guidelines, selecting machines with the right security features, and implementing safety first. Note that you can always input just things that are relevant for you, injecting some technical data such as the one you need to remember to avoid trouble on the charges you are under.

Comments

Post a Comment