The Benefits of Using Copper-Coated Welding Wires

Welding is simply the process of joining heats two metals together. Welding wire is one of the essential equipment in the welding process. The wire fills in the metal to help them adhere to one another. One of the most common types of welding wires preferred by welders is the copper-coated welding wires due to its benefits. Here is how these wires can help us.

Welding Improvement: The Role of Copper-Coated Welding Wires

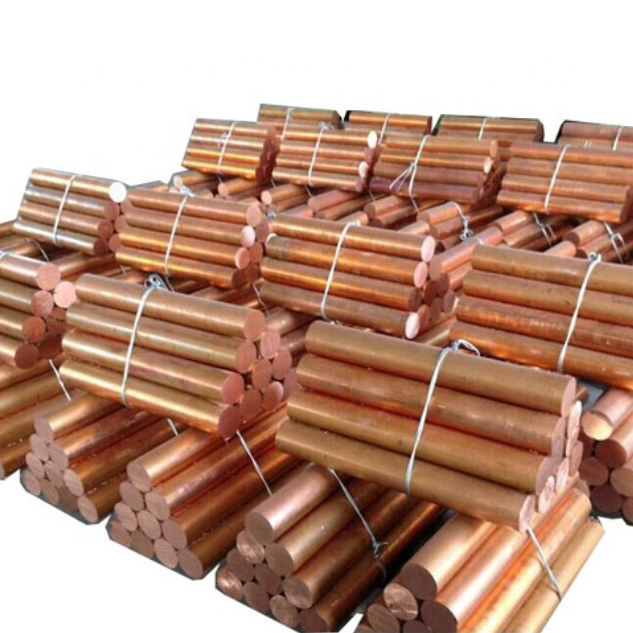

Copper-coated welding wires are those that have a thin layer of copper on its outside. This aids electricity in flowing more smoothly during welding. This Thermocouple Series makes a robust and stable arc when the electricity flows readily through it. This helps welders put clean and accurate welds. This in turn leads to higher quality end products.

Copper-Coated Wires Making It Possible to Save Time and Resources

The use of welding wires with copper coating can save both time and material. Since they conduct electricity better, welders are able to work faster. It means they are able to complete their projects faster. The copper plating also aids in lessening spatter, which is the little, scattered pieces of liquid metal that can blow away when welding. Less spatter also means less cleanup time, less waste.”

Utilizing a Copper-Coated Welding Wire for Consistent and Reliable Joints

Discover why consistency and reliability are so crucial in welding. Welding wire is copper-coated for these purposes. But better flow of electricity forms a stable arc that produces more consistently well-welded seams. That gives welders greater confidence that their welds will hold.

How to Stopping Rust and Corrosion in Welded Joints

One of the biggest challenges in welding is preventing rust and corrosion. CuNi Alloy possess a layer of copper coating on them to protect them from such problems. Welders use these wires to ensure that the joints they connect remain strong and last a long time.

An Affordable Alternative to Fulfill Your Welding Requirements

Copper-plated welding wires can mean savings for welders too. Welders who use better and more reliable means can decrease the risk of repairs or redo work. This saves time and money in the long run. And, by preventing rust and corrosion, the finished product lasts longer, translating into more savings.

To sum up, specifically, Precision Alloy have several advantages that enhance the welding procedure. Giving welders everything from improved electricity flow and weld quality to saving time and resources, these wires are a great aid. Welder can benefit with great welds, maintain rust and corrosion resistance, and save money by using Copper coated welding wires. Try DLX copper-coated welding wires for your next project and you might be amazed.

Comments

Post a Comment